We often see rods for repair with damage that could have been avoided. We hope this information will help with understanding the structure and behaviour of your rods so that you will be able to make sure you are not back in the shop asking for a repair instead of fishing!

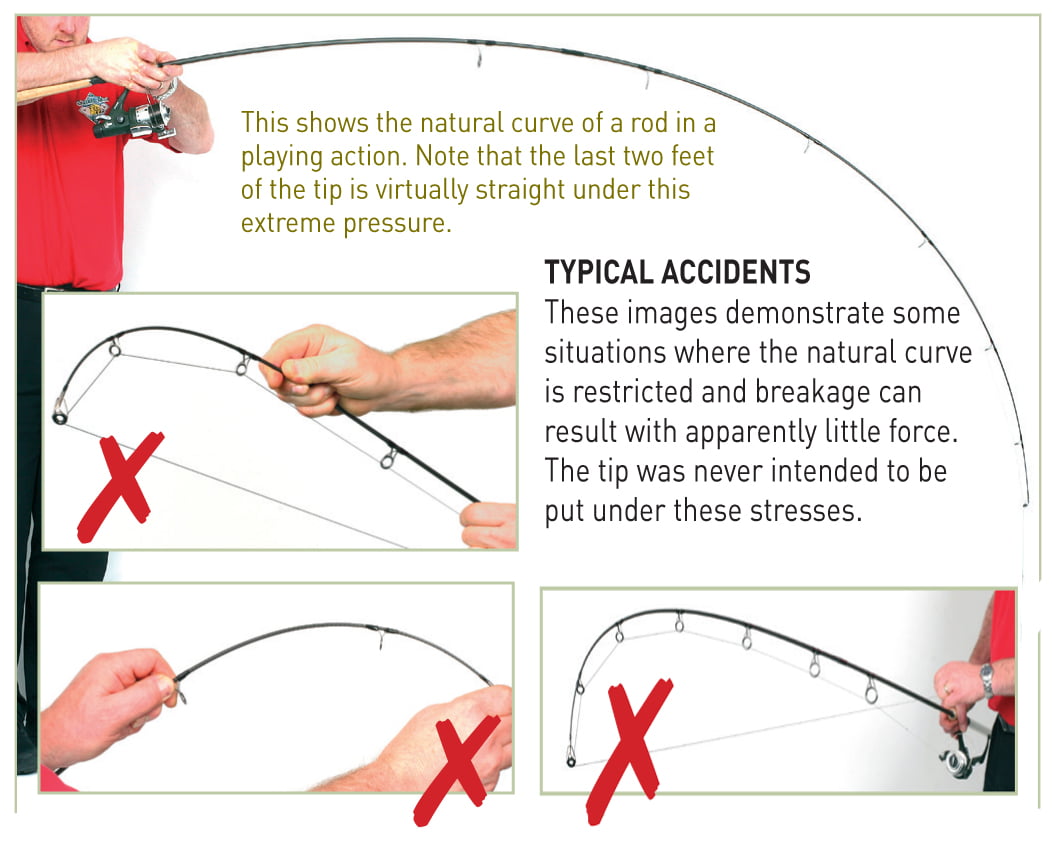

NATURAL CURVE

A little understanding of how pressure is distributed throughout a rod blank will result in a lower chance of breakages due to accidental mishandling.

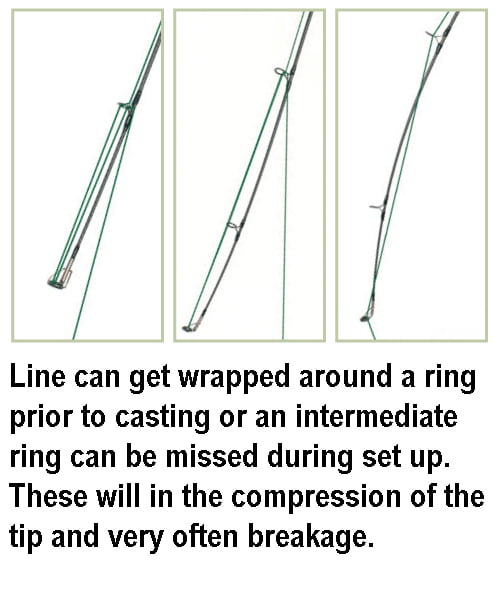

The natural curve of a rod is when the full length of the rod is used in a casting or playing action (as indicated). In this situation the rod is very strong, because as the pressure increases, the forces travel down the blank towards the larger diameter of the butt, which is designed to deal with this build-up of pressure. However, if the natural curve is interfered with or restricted in some way, accidental breakages can occur.

The tip, being the thinnest part of the rod, is the most vulnerable section and the least understood.

When testing the action of a rod as you would in a tackle shop, hold ONLY the tip ring. Avoid grabbing a few inches of the tip, as this can not only potentially result in breakage, but will also throw out the action and test curve of the rod, giving you a false test. The best way to test the action of a rod is to put a reel on, thread the line through the rings and get somebody to hold the line whilst you bend into it in the same way as you would in a fishing session.

MANUFACTURING FAULTS

With the advanced technology being used nowadays manufacturing faults are rare, but if there is a fault that affects the strength of the rod, it will normally reveal itself the first or second time the rod is used.

Types of manufacturing faults may be:

Over-grinding of the blank

Revealed by a much thinner wall existing on one side of the break.

Rolling process defects

These are usually twisting of the carbon fibres or a foreign object gets rolled into the blank during the rolling process. On close inspection of the break irregular folds or the object will be seen.

IMPACT OR PRESSURE POINT DAMAGE

These are the cause of many seemingly unexplainable breakages. An invisible fracture can occur if a rod receives a short sharp impact or is put under pressure during storage or transportation. The weak point created may then cause a breakage the next time the rod is used.

Many impact fractures show tell-tail marks around the break, but pressure point fractures can leave no evidence of the cause. Most carp rods are very durable and can withstand heavy handling, but care should always be taken to make sure they are handled, transported and stored in a way that prevents these problems.